Panas stainless steel stainless un unangan nut

Kirim Pitakonan

Panas baja stainless steel un Sisip bagean nut yaiku kacang sing kuwat kanthi benang ing njero. Dheweke digunakake nalika sampeyan pancene butuh perkara sing kenceng. These nuts have a bumpy outside surface. Sampeyan menet menyang bahan kaya logam, plastik, utawa komposit kanggo nggawe sambungan padhet. Perawatan panas ndadekake Un masang nut ekstra. Pramila dheweke wis digunakake ing papan sing angel kaya aeroangkace utawa nggawe mobil, ing ngendi bagean pasuryan goyang lan nggunakake abot. Desain kasebut mbantu tetep lan tetep suwe, sanajan ditarik utawa stres.

Perks Utama

The main perks of heat treated stainless steel UN insert nuts are their really strong tensile strength and ability to resist corrosion. Panas nambani kacang iki ndadekake dheweke terus bobot nganti 40% luwih bobot tinimbang kacang baja tahan karat biasa. Ing njaba njaba (atos) ora ana sing muter yen wis diinstal. Kacang kasebut mlaku kanthi apik ing papan sing angel, kaya papan sing nganggo banyu asin, bahan kimia, utawa panas / adhem, tanpa nganggo. For engineers, using these nuts means less worry about reliability. Dheweke ngethok biaya pangopènan lan sawetara masalah Majelis sing luwih sithik ing struktur utawa mesin.

Apa kelas baja stainless khusus digunakake kanggo lan ngapa?

Baja steel stainless steel kita sing ora bisa digunakake ing baja stainless 316L. Jinis Austenitic iki pancen apik kanggo nglawan karat, utamane nglawan klorida. That makes these nuts a great choice for tough marine, chemical, and outdoor uses where they need to last a long time.

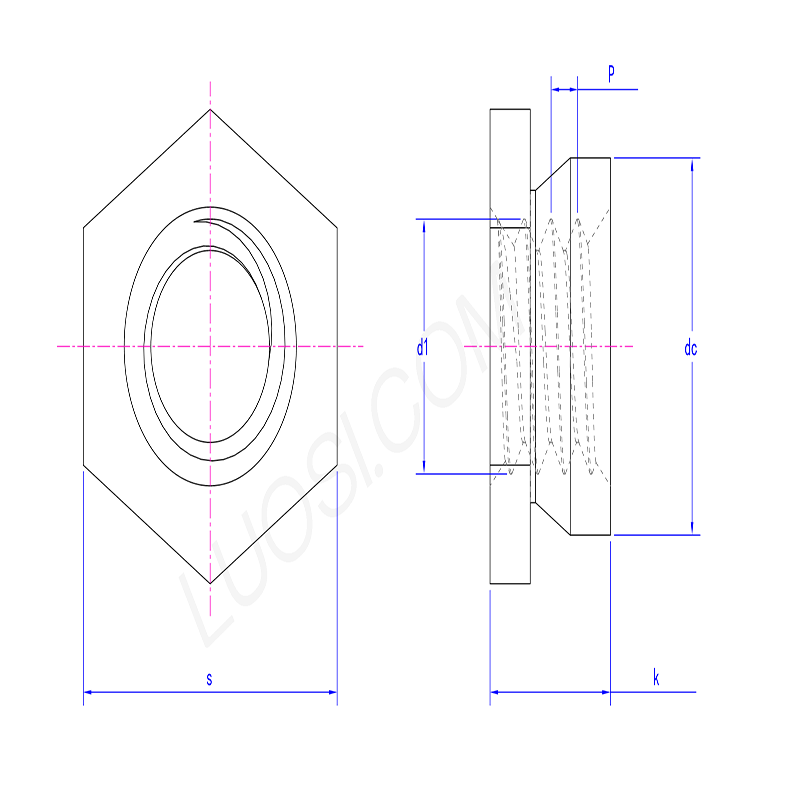

Parameter Produk

| Mon | 440-1 | 440-2 | 623-1 | 632-2-2-2-2-2 | 832-1 | 832-2-2-2 | 032-10-1 | 032-2-2 | 0420-3 | 0420-4 | 0420-5 |

| P | 40 | 40 | 32 | 32 | 32 | 32 | 32 | 32 | 20 | 20 | 20 |

| D1 | # 4 | # 4 | # 6 | # 6 | # 8 | # 8 | # 10 | # 10 | 1/4 | 1/4 | 1/4 |

| DC Max | 0.171 | 0.171 | 0.212 | 0.212 | 0.289 | 0.289 | 0.311 | 0.311 | 0.343 | 0.343 | 0.343 |

| k max | 0.06 | 0.09 | 0.06 | 0.09 | 0.06 | 0.09 | 0.06 | 0.09 | 0.12 | 0.151 | 0.182 |

| s | 0.188 | 0.188 | 0.25 | 0.25 | 0.312 | 0.312 | 0.343 | 0.343 | 0.375 | 0.375 | 0.375 |