Nut nut kenceng

Kirim Pitakonan

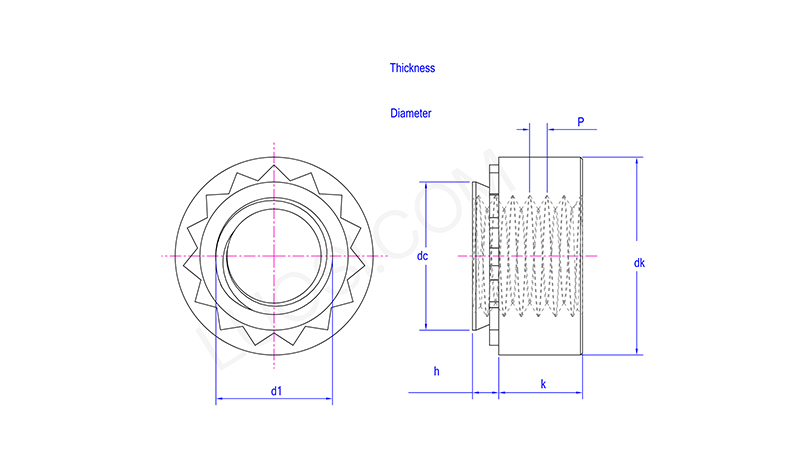

Alasan inti kanggo macem-macem gegayutan kanthi mantep, saéngga nut kenceng sing bisa digunakake kanthi macem-macem bahan ductile. Ing praktik, umume digunakake kanthi macem-macem bahan, kalebu wesi sing entheng, wesi aluminium kanthi baja stainless-stainless-stainless-stainless steel sing paling apik kanggo mindhah nalika kliwat tanpa mecah. Kepiye materi uga penting. Saben jinis nut nut kenceng duwe macem-macem kekandelan bisa, biasane sekitar 0.5mm nganti 6mm (0,020 "nganti 0.236"), gumantung karo ukuran nut lan kepiye materi kasebut.

Kauntungan produk:

Nggunakake kacang-kacangan sing kuat bisa ngirit dhuwit akeh. Sampeyan ora butuh peralatan sing welding, wong-wong supaya mbukak welders, energi kanggo welding, utawa persediaan sing ana karo barang-barang kasebut kanggo njupuk asile lan tetep aman.

Selehake dheweke pancene cepet banget. Kanthi mencet otomatis, masing-masing-masing biasane mbutuhake sawetara detik, tegese sampeyan bisa nggawe luwih murah. Sampeyan uga nggunakake bagean sing luwih sithik - ora perlu cuci utawa cuci cuci - supaya nangani lan nglacak bagean luwih gampang.

Dibandhingake karo welding, ora ana sing paling akeh. Lan wiwit dirawat kacang-kacangan sing kuwat terus maju, sampeyan kurang saka jaminan lan kesalahan ndandani. Kabeh sing ndadekake dheweke dadi cara sing murah kanggo nyepetake prekara nalika sampeyan nggawe akeh.

| Mon | 440-2 | 632-1 | 632-2-2-2-2-2 | 832-1 | 832-2-2-2 | 024-1 | 024-2 | 032-10-1 | 032-2-2 | 0420-1 | 0420-2 |

| P | 40 | 32 | 32 | 32 | 32 | 24 | 24 | 32 | 32 | 20 | 20 |

| D1 | # 4 | # 6 |

# 6 |

# 8 |

# 8 |

# 10 |

# 10 |

# 10 |

# 10 |

1/4 | 1/4 |

| DC Max | 0.343 | 0.212 | 0.212 | 0.233 | 0.233 | 0.295 | 0.295 | 0.295 | 0.295 | 0.343 | 0.187 |

| Diameter saka dipasang bolongan min |

0.344 | 0.213 | 0.213 | 0.234 | 0.234 | 0.296 | 0.296 | 0.296 | 0.296 | 0.344 | 0.1875 |

| Diameter saka dipasang bolongan maksimal |

0.347 | 0.216 | 0.216 | 0.237 | 0.237 | 0.299 | 0.299 | 0.299 | 0.299 | 0.347 | 0.1905 |

| DK Max | 0.45 | 0.29 | 0.29 | 0.32 | 0.32 | 0.38 | 0.38 | 0.38 | 0.38 | 0.45 | 0.26 |

| DK Min | 0.43 | 0.27 | 0.27 | 0.3 | 0.3 | 0.36 | 0.36 | 0.36 | 0.36 | 0.43 | 0.24 |

| H max | 0.087 | 0.038 | 0.054 | 0.038 | 0.054 | 0.038 | 0.054 | 0.038 | 0.054 | 0.12 | 0.038 |

| h coder | 2 | 1 | 2 | 1 | 2 | 1 | 2 | 1 | 2 | 3 | 1 |

| k max | 0.18 | 0.1 | 0.1 | 0.14 | 0.14 | 0.17 | 0.17 | 0.17 | 0.17 | 0.18 | 0.1 |

| K Min | 0.16 | 0.08 | 0.08 | 0.12 | 0.12 | 0.15 | 0.15 | 0.15 | 0.15 | 0.16 | 0.08 |

| Ketebalan saka plate mine min |

0.091 | 0.04 | 0.056 | 0.04 | 0.056 | 0.04 | 0.056 | 0.04 | 0.056 | 0.125 | 0.04 |

Instal peralatan sing dibutuhake:

Nginstall nut mbutuhake peralatan pers spesifik, biasane pers hidraulik utawa listrik servo-listrik. Alat kleming darmabakti (punch lan mati set) dipasang ing pers, sing dirancang kanggo ukuran nut nut lan ketebalan lembar. Alat kasebut ditrapake kanthi dhuwur, tekanan lokal kanggo ngrusak lembaran ngubengi basis sing di.